TECHNICAL BLOG

Precise control over qubit frequencies post-fabrication

- Electron-beam (e-beam) annealing of Josephson junctions offers precise control over qubit frequencies post-fabrication.

- By locally tuning the resistance of JJs, our technique enables the reduction of frequency spread among qubits, leading to improved allocation and reduced collisions.

- Our findings have promising applications in further ensuring the scalability, and performance, of OQC tech.

Connor Shelly

DIRECTOR OF MATERIALS SCIENCE & DEVICE ENGINEERING

As the Director of Materials Science and Device Engineering, Connor is responsible for the manufacturing of OQC’s qubits, QPUs, and superconducting devices, as well as being responsible for areas including qubit coherence, cryogenic packaging, materials science, and nanofabrication. Prior to joining OQC, Connor worked at the National Physical Laboratory (NPL) where he was the lead researcher for the Superconducting Electronics team and worked on the development of quantum limited amplifiers and carried out research into the physics of superconducting nanobridges as Josephson elements.

Robust, large-scale, quantum processors are fundamental to facilitating reliable quantum computations for real-world applications. Central to this challenge is preserving qubit accuracy as the number of qubits scales. These qubits, the building blocks of quantum processing units (QPUs), must exhibit traits like prolonged coherence time (the ability to exist in multiple states simultaneously), gate fidelity, and minimal cross talk between neighbouring qubits, a task complicated by fabrication imperfections that can impact the ability to manufacture qubits with the frequencies exactly as designed.

Addressing fabrication imperfections

Superconducting qubits are a widely used platform in universal gate-based quantum computing. Fixed-frequency transmons have demonstrated high gate fidelities, are simple to manufacture, and typically require less control complexity than tunable transmons. However, despite their promise, fixed-frequency transmons face challenges in achieving precise frequency targeting at scale due to the all too common challenge of fabrication imperfections.

Imperfections during manufacture leads to variability in the Josephson Junction (JJ) properties. This variability in JJ properties imparts a variability in the qubit frequencies. These challenges require a technique to individually fine-tune JJs post-fabrication. With this in mind our R&D team developed e-beam tuning as a technique for reducing qubit frequency variability in order to enhance QPU performance in OQC quantum computers.

What are Josephson Junctions?

The Josephson Junction, predicted by British theoretical physicist Brian Josephson in 1962, consists of a thin non-superconducting layer between two superconducting layers. These junctions serve as the foundation for superconducting quantum circuits, they are the circuit element that provides the nonlinearity that is required to make a qubit.

Post Fabrication control

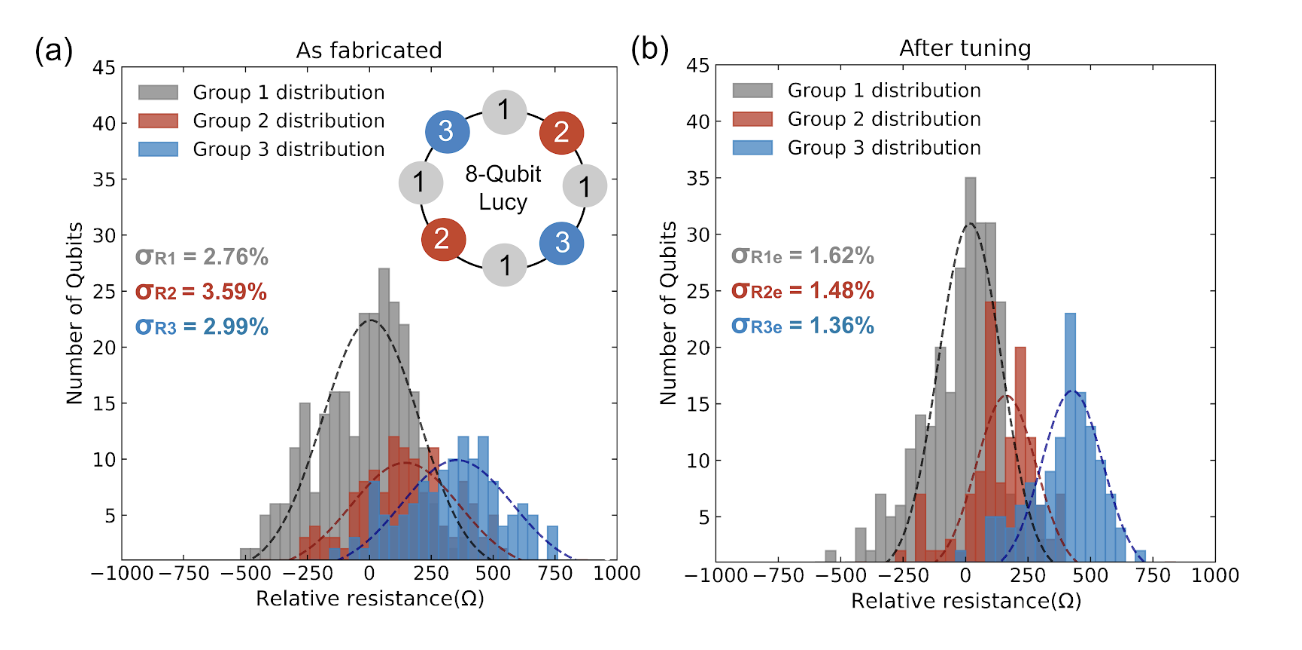

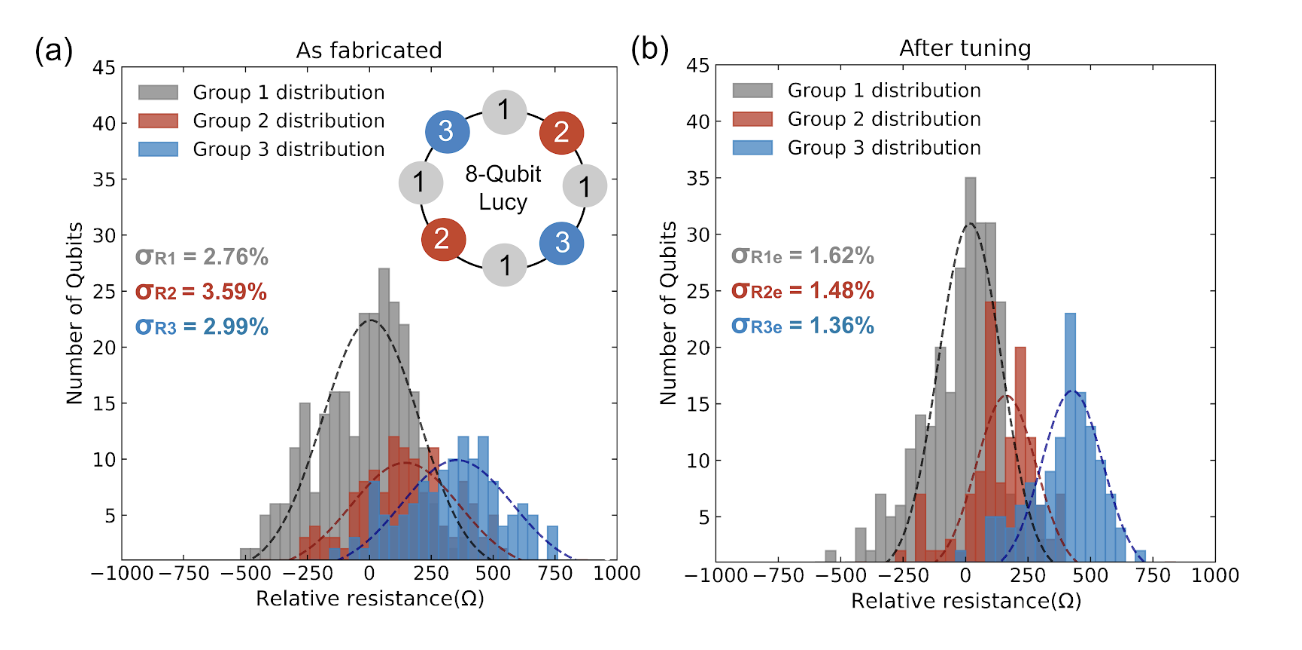

The R&D Team at OQC developed electron-beam annealing as it offered several advantages over traditional annealing methods. It allows for precise control over the annealing process, as the energy and intensity of the electron beam could be adjusted to achieve the desired effect. We have successfully utilised an electron beam (e-beam) to locally anneal JJs, reducing variability in the tunnel barrier resistance. When applied to a wafer of QPUs, it resulted in a significant reduction in resistance spread – achieving resistance spreads of less than 1.5% – minimising expected frequency collisions and thus increasing the yield of viable QPUs.

Figure 1:(a) As-fabricated Josephson junction resistances from a typical OQC Lucy-8QPU wafer. JJ resistances are in three separate design groups 1, 2, and 3, designated by the colours grey, red, and blue. (b) The same wafer having undergone our electron-beam annealing process. The spread of each JJ group is reduced.

These results show that electron-beam annealing can be used as a tool to reduce JJ resistance spread to beyond the state-of-the-art as-fabricated Josephson junctions. By integrating this novel technique [arXiv:2402.17395v1 [quant-ph] 27 Feb 2024] into our existing fabrication workflows, we can enhance qubit frequency allocation, reduce frequency collisions, and ultimately further improve the scalability and reliability of our technology.

Join our newsletter for more articles like this

By clicking ‘sign up’ you’re confirming that you agree with our Terms & Conditions